WEIGHING FILLING AND DOSING

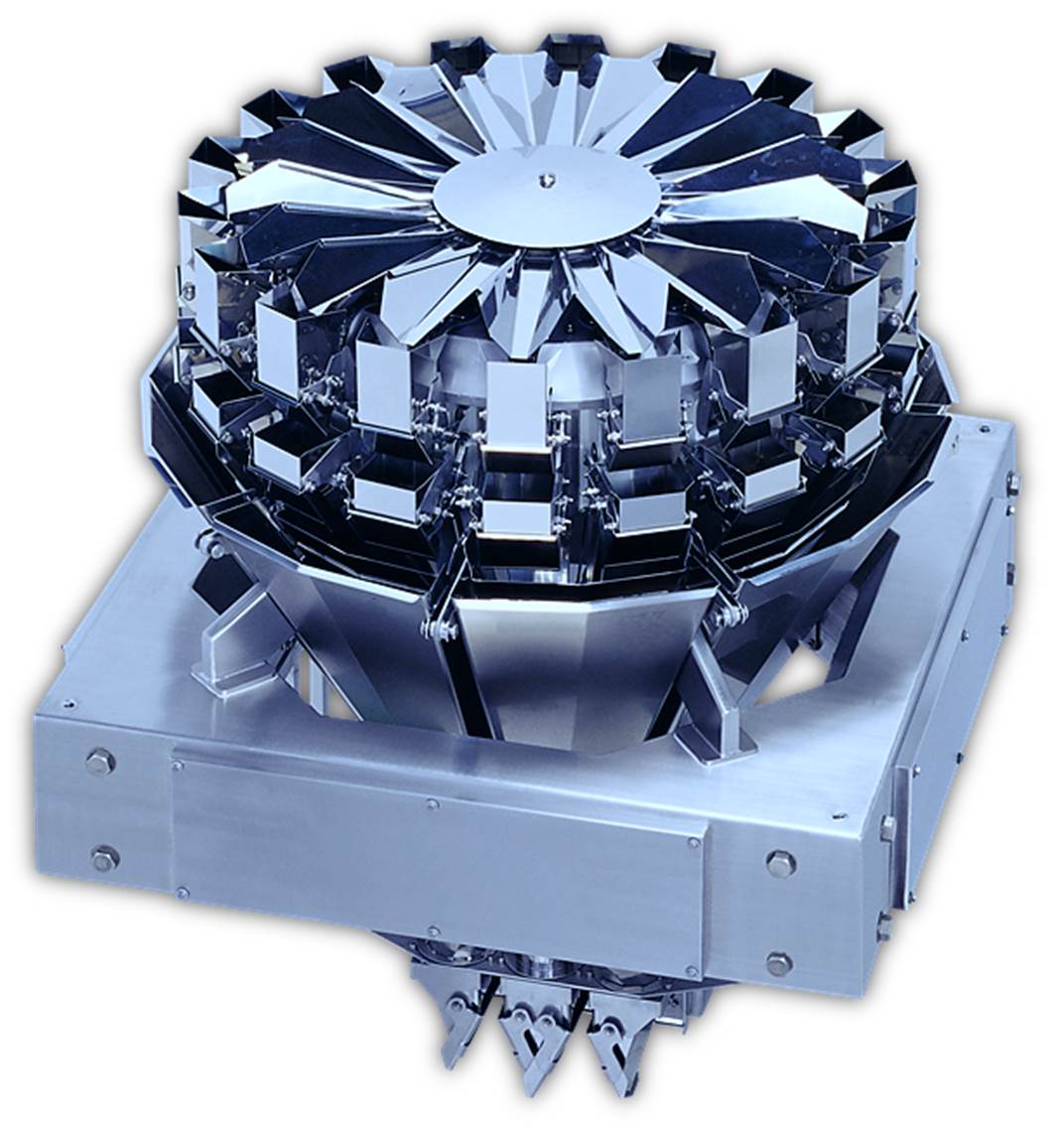

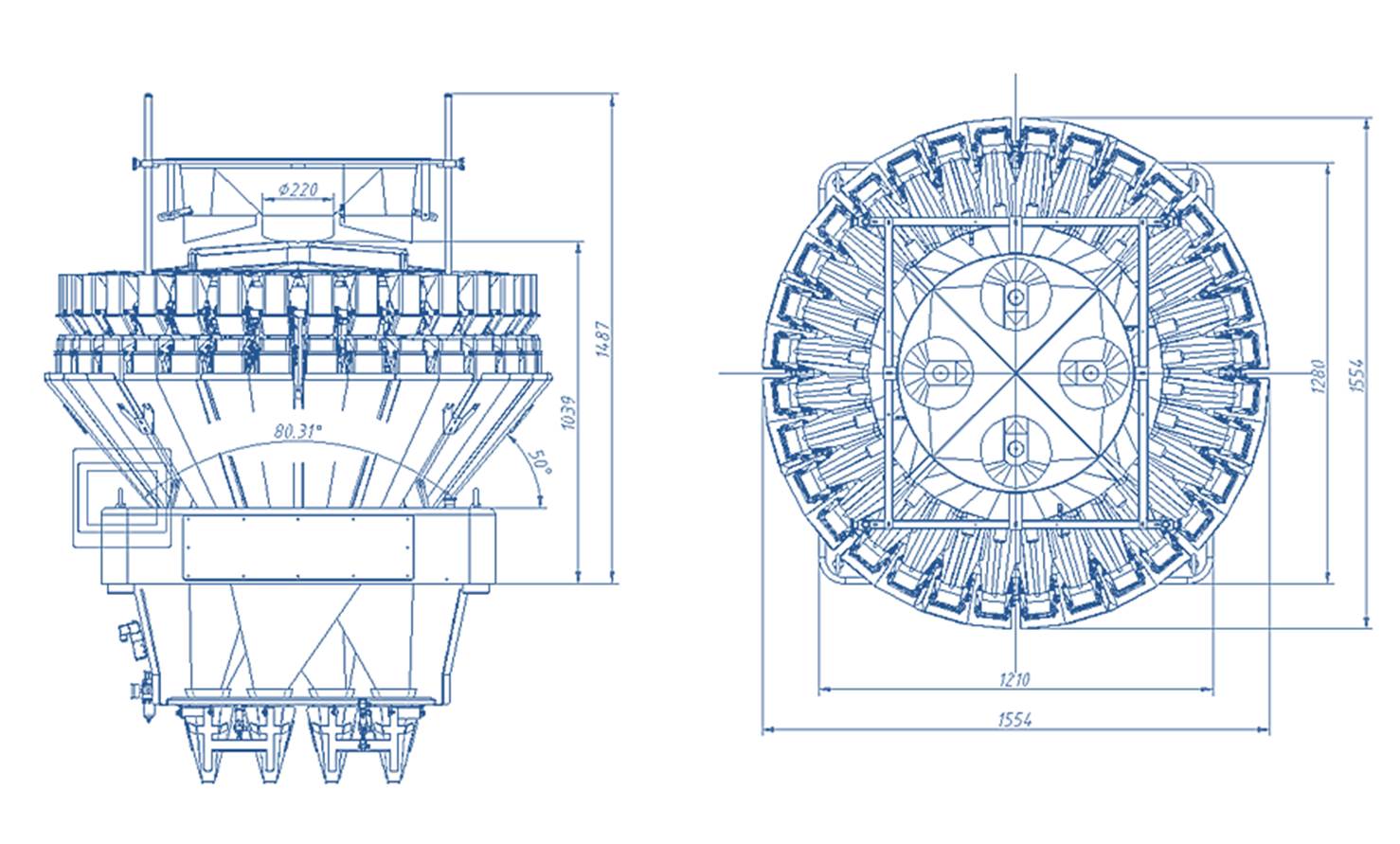

Multihead filling solutions

- Adapted to your requirements of bottle, jar, can or other special formats.

- Connection with multiple brands of weighers. Signals and mechanical synchronization.

PRODUCTS

Chips packaging

MHF-Filler 100

Up to 200 bags/jars per minute

Automatic bag filler

AMHBF-900

Machine accepting

Coffee packaging

MHF-Filler 200

Up to 120 bags/jars per minute

Jars / bottles filler

AMF-Filler 450

Adaptable filler for most formats, speeds and budgets

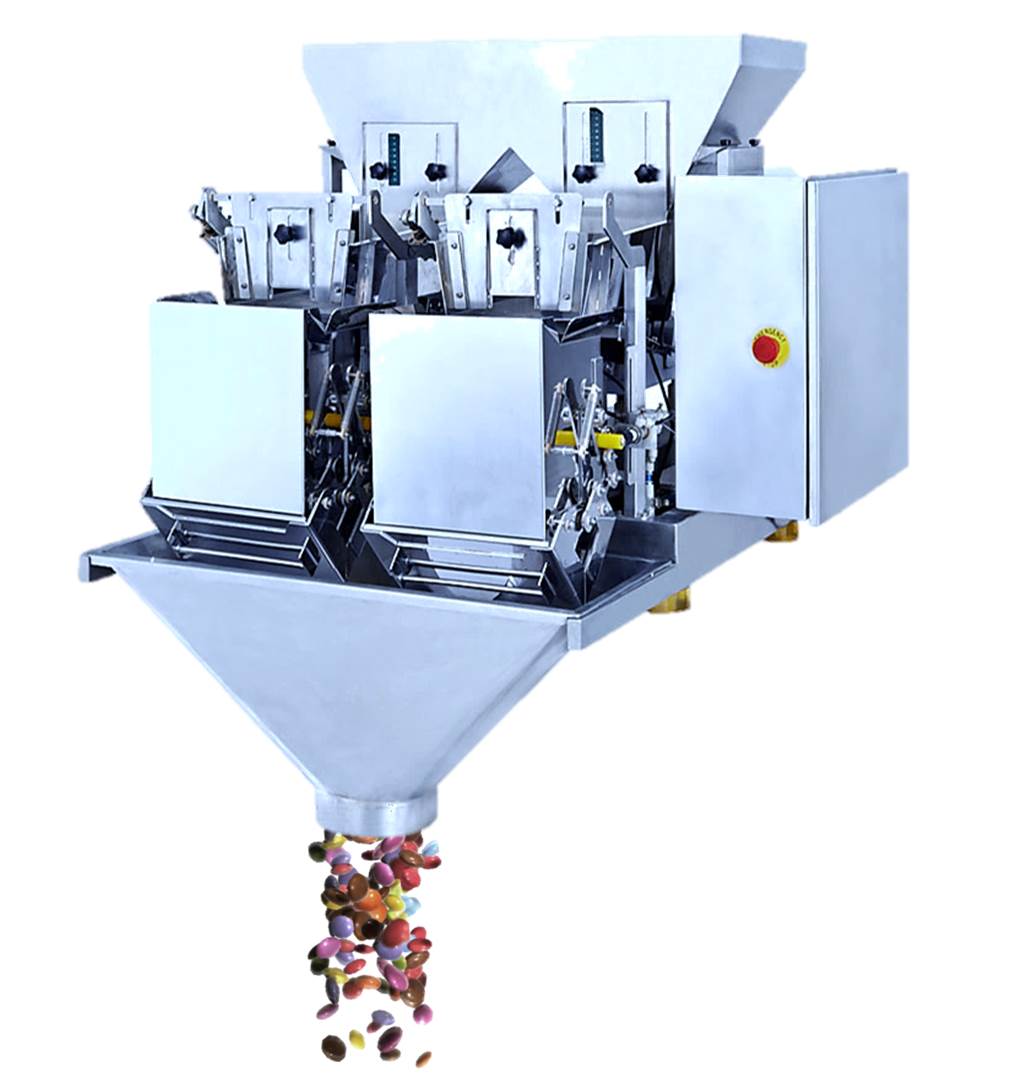

Candies packaging

MHF-Filler 300

Up to 100 bags/jars per minute

Bag filling

AMHBF-500

Machine ready for premade and from roll bags

Grains and bulk product fillers

- Ready for multiple food product filling. Such us

candies, biscuits, snacks, cereals, poultry, meat, fish, confectionery, fresh or frozen products, pet food, ready meals, dairy, pasta, powder and coffee.